TEST PRINCIPLE

To determine the firmness of lipstick by bending samples with a Lipstick Cantilever Fixture (TA-LC) using a CTX Texture Analyzer.

BACKGROUND

Lipstick is a cosmetic product applied to the lips to add texture, color, and protective benefits. Lipsticks come in several shades and styles. Ingredients include wax for structure, oils for a shiny or glossy appearance, pigments for color, and emollients to smoothen and soften the skin.

Lipsticks were stored at room temperature for 24 hours before testing. A CTX Texture Analyzer with a 1.5 kg load cell was used with a TA-LC Fixture to perform a bend test.

This test bends the lipstick to a set distance and measures the amount of force required to bend the lipstick. This bend test measures the firmness of the lipstick. As the probe retracts, the stickiness of the lipstick will be measured. Lipstick samples will be placed inside the TA-LC bottom fixture, attached to the Fixture Base Table (TA-BT-KIT). As the probe is lowered onto the sample, it will make contact and bend the lipstick. This will provide data on the hardness of the lipstick.

METHOD

| Equipment: |

CTX with 1.5 kg Load Cell (XCTX) |

|

Fixture Base Table (TA-BT-KIT) |

|

Lipstick Cantilever Fixture (TA-LC) |

|

Texture Pro Software (SWL-02-111) |

Settings:

| Test Type: |

Compression |

| Test Speed: |

1.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

7 mm |

| |

|

PROCEDURE

- Attach the TA-LC probe to the CTX Texture Analyzer.

- Insert two table bolts into slots on the analyzer base.

- Place the Fixture Base Table on the CTX, and slightly screw on the bolt nuts.

- Adjust the table so that the probe is at the center of the table. Attach the TA-LC bottom to the base table. Slightly tighten side screws.

- Once alignment is complete, secure the base table by tightening the bolt nuts.

- Place the lipstick sample in the hole on the TA-LC bottom. Extend lipstick 12.5 mm past the tube and tighten the screw.

- Align the sample under the probe at the center.

- Position the probe to about 3 mm above the sample.

- Set the test parameters using the Texture Pro software.

- Commence test.

- Wipe the probe with a dry cloth after testing each sample.

- Repeat steps 1-11 for all test samples.

OBSERVATION

When a trigger load of 10 g is detected at the sample surface, the probe starts to bend the lipstick sample at a test speed of 1 mm/s over a specified distance of 7 mm. Once the 7 mm distance is met, the probe returns to the starting position.

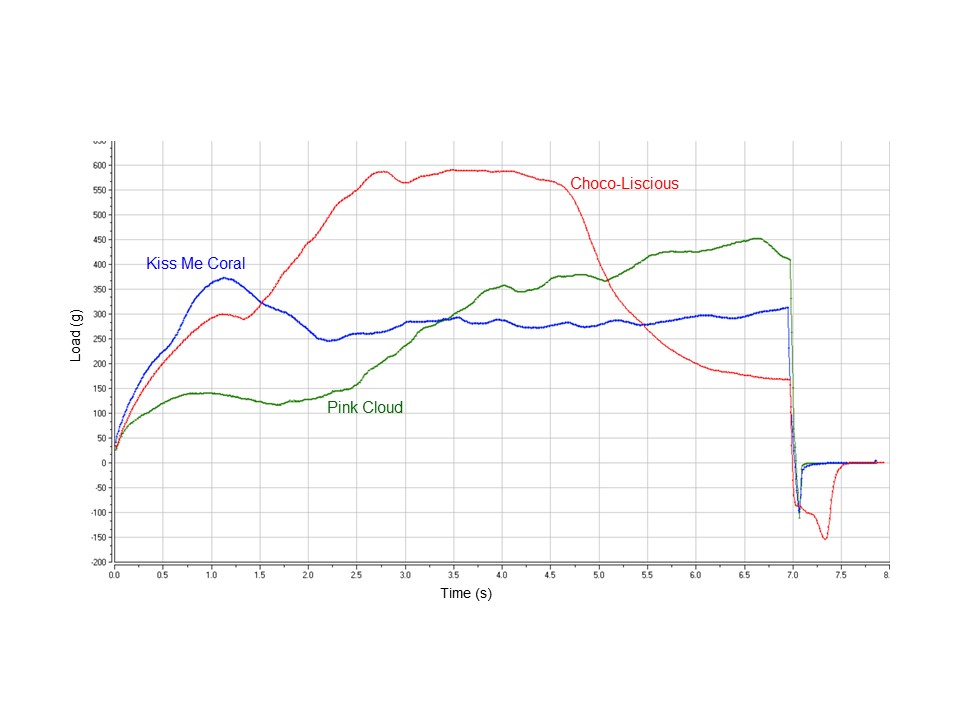

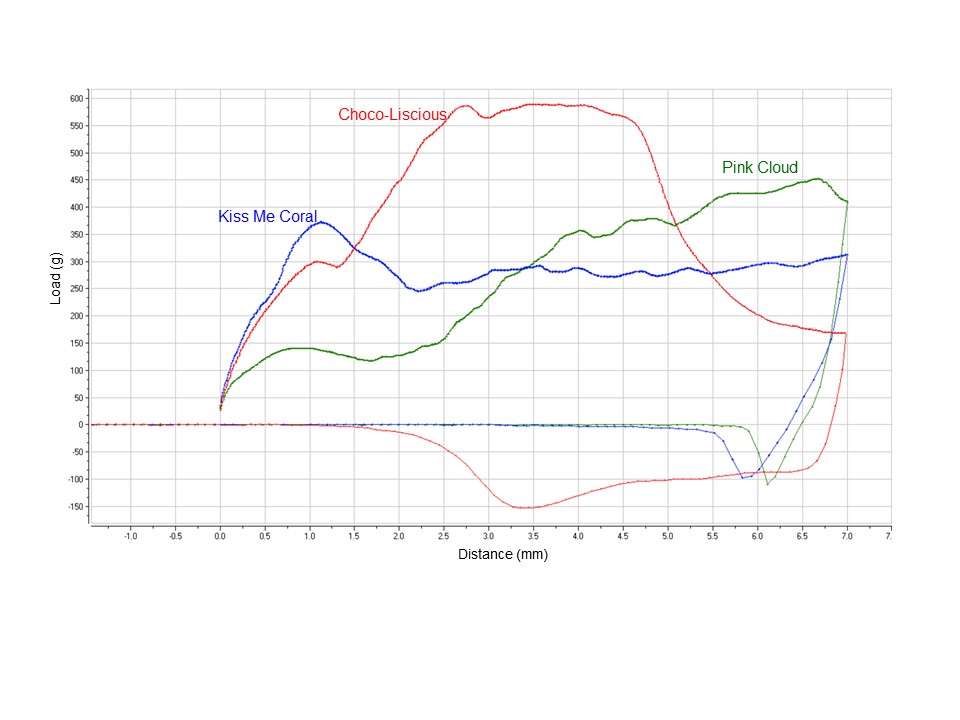

The Load vs. Time graph (Fig. 6) indicates the sample Hardness (Peak Load) and stickiness (Adhesive Force). The Adhesiveness is the total area under the negative curve found in the Load vs. Distance graph (Fig. 7). It indicates the work done on the sample to bend it a set distance and the Adhesiveness of the sample.

Typical Load vs. Time graph. The axes are Load (g) vs. Time (sec)

Typical Load vs. Distance graph. The axes are Load (g) vs. Distance (mm)

DISCUSSION

The maximum force value is the Peak Load. It is a measure of the sample ‘hardness.’ The higher the value, the harder the sample. The higher the Peak Load, the more work is required to bend the sample. Adhesive Force is the amount of force required to overcome the attractive bonds between the sample (lipstick) and external surfaces in contact with it (probe). Adhesiveness is the amount of work required to pull the sample away from these external surfaces.

DATA REPORT

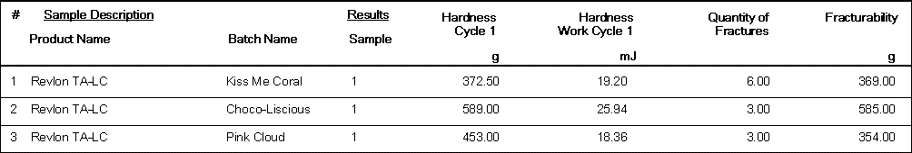

TexturePro software is used to program and control the CTX Texture Analyzer during experimental tests. It automatically calculates Peak Load values and Hardness Work Done. Multiple samples can be run if desired, and calculated values for standard deviation can be reported.

Results of the tests performed on three different lipstick samples

CONCLUSION

The test results can be used to determine the ideal hardness and stickiness of the lipstick. The test procedure, sample preparation, and equipment setup must be adhered to for reproducible test results.

>>Download pdf of this application note.