TEST PRINCIPLE

Evaluating the breaking strength of dry lasagne using a three-point bend accessory (TA-TPB).

BACKGROUND

The snap characteristics of dry lasagne can be determined using the three-point bend assembly

The sample is supported at two points by the adjustable supports that are equidistant form each other at a distance that will support the sample.

The flexure probe is connected to the probe shaft of the instrument and the lasagne sheet placed on the two adjustable supports. As the probe travels down at a given test speed a force is applied at the sample surface until the sample snaps along its width creating a single fracture at the point of contact with the probe.

The three point bend test can be used to improve production consistency in order to maintain an “ideal” texture. Parameters of interest are hardness, fracturability/brittleness, and first fracture deformation. The fracturability is the force required to generate the first fracture and the first fracture deformation is the distance to snapping point. This value gives an indication of the flexibility of the sample.

The brittleness (fracturability) measurements from the test reflect on the breaking characteristics of the sample and can be used to optimize product formulation (e.g., moisture content, mixing time, temperature, gluten strength), and handling during manufacture.

The quantity of fractures measurement from the test can be used to establish a sensory preference for the product during product development.

Depending on the texture of the lasagne, the fracturability value can be the same as the hardness value if the sample fractures only once when breaking. Collectively, the fracturability, hardness and quantity of fractures measured in the test will give a good indication on the effects of formulation changes and process control.

METHOD

Equipment:

| Instruments: |

CTX with 5Kg Loadcell |

| Accessory: |

TA-BT-KIT Fixture Base Table

TA-TPB 3-Point Bend Assembly |

| Software: |

Texture Pro Software |

Settings:

| Test Type: |

Compression |

| Pre-Test Speed: |

2.0 mm/s |

| Test Speed: |

3.0 mm/s |

| Post-Test Speed: |

3.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

5.0 mm |

| Trigger Force: |

15 g |

SAMPLE PREPARATION

Remove the sample from the place of storage just prior to testing. Avoid exposing the sample to moisture.

PROCEDURE

- Attach the flexure probe to the probe shaft of the instrument.

- Place the fixture base table to the base of the instrument and loosely tighten the thumb nuts to enable some degree of mobility.

- Insert the three point bend assembly onto the fixture base table and tighten into position using the thumb screws.

- Using the scaled markings on the support, adjust the two adjustable supports such that they are of equal lengths apart. The selected distance should be able to support the sample.

- Lower the arm of the instrument to a few millimeters above the base of the supports and centrally align the two supports to the flexure probe above by re-positioning the fixture base table until the flexure probe is equidistant to the two supports.

- Once alignment is complete, tighten the thumb nuts of the fixture base table to prevent further movement.

- Raise the instrument arm to provide room to place the sample.

- Remove the sample from storage and place it centrally over the supports.

- The starting position of the instrument arm is optional. Having the probe in close proximity to the sample surface is preferable in order to quicken the test. The flexure probe should however not touch the sample surface.

- Commence the test.

RESULTS

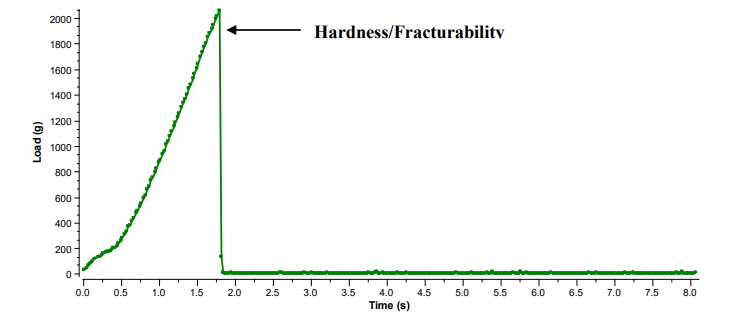

Figure I

Figure I A load/time graph to show the breaking strength of dry lasagne using a three point bend accessory. The maximum force value is a measure of sample hardness. The fracturability of the sample is measured at the force that generates the first fracture. The fracturability value for this sample is similar to its hardness value indicating that the sample immediately snaps once its resistance to the compressive force has been exceeded. The gradient of the graph can also be measured to give sample stiffness.

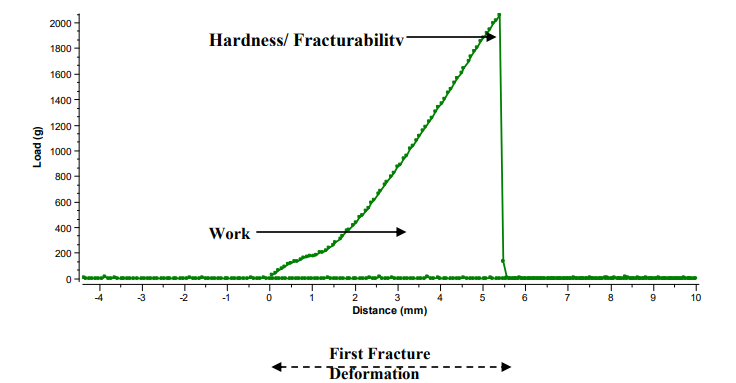

Figure II

Figure II A load/distance graph to show the breaking strength of dry lasagne using a three point bend accessory. This is an alternative option for displaying the results. The graph shows similar information to the load/time graph with two additional measurements. It is from the load/distance graph alone that the work done and flexibility of the sample can be measured. The first fracture deformation distance is an indication of sample flexibility such that the longer the distance, the more flexible the sample. The work done is the area under the graph and is the energy required to overcome the strength of the internal bonds within the sample.

Note: If only noodles are being tested and there is no requirement for any other type of pasta a 1000 g or even 100 g CT3 instrument may be used for this test

OBSERVATIONS

When a trigger load of 15 g has been attained at the sample surface, the probe proceeds to compress the sample at a test speed of 3 mm/s over a distance of 5 mm. During this time, the force is seen to rapidly increase. When the applied force exceeds the force of resistance by the sample, the sample reaches its breaking point and snaps seen by the sudden drop in the load/force values to zero. The maximum force value is a measure of sample hardness (breaking strength). The area under the graph from the load/distance graph (Figure 2) is a measure of work done. The gradient of the graph can also be measured to give an indication of sample stiffness; the steeper the gradient, the stiffer the sample. From the load/distance graph, the distance to breaking point (first fracture deformation) gives an indication of sample flexibility. This is an indication of how far a sample can be deformed before fracture. The table below summarizes the average results of four samples:

| Sample |

Hardness (g) |

Fracturability (g)

|

Work Done(mJ) |

Quantity of Fractures |

1st Fracture Deformation (mm) |

| Dry Lasagne |

2114 ± 61 |

2114 ± 61 |

47.9 ± 2.9 |

1 |

5.41 ± 0.12 |

As the quantity of fractures generated with this sample is one meaning that for this sample, the fracturability value will be the same as its hardness value.

>>Download PDF of this application note.