TEST PRINCIPLE

Evaluation of the hardness of potatoes with different cooking times by compression using the CTX and Kramer shear cell

BACKGROUND

TPotato cells have a rigid cell wall that is a polymer network of polysaccharides with the middle lamella making up the outer layer of the cell wall. The middle lamella comprises mainly pectic material and binds the cells together. During heating, the structure of the cell wall is affected resulting in a loss of cell adhesion. The integrity of the cell membrane is also lost resulting in loss of turgor pressure and free diffusion of cellular contents. Consequently, starch grains within the cells absorb water and swell to form a gel. Heating potatoes therefore causes the swelling of starch grains and a softer tissue whereby the cells are more easily separated. The extent at which these processes occur depends on the cook time. When cooked potato is subjected to a compressive or shear force, the failure of the potato occurs at the middle lamella. Therefore, the cell wall composition and structure greatly determine the texture of the final potato product.

The texture of potatoes can be described by mealiness (mouth feel), waxiness, sloughing, and firmness. The firmness is related to starch swelling and gelatinization as well as stability of the pectic substances in the cell wall and middle lamella.

The texture analyser can measure the firmness, shear, elasticity, and adhesiveness of potatoes in a compression test; in addition, the cohesiveness, chewiness and gumminess can be measured in a Texture Profile Analysis test (TPA).

This application measures the firmness of potatoes at different cook times using the Kramer shear cell. The Kramer shear cell with its multiple blades can shear samples of variable geometry meaning that the hardness and work done results are an average of the forces required to shear the sample. The test method incorporates the textural methods of compression, shearing and extrusion through slots in the base of the cell.

Texture analysis of potatoes can be used for quality control purposes, predicting consumer acceptance of the product, performing shelf-life studies, and studying the effects on texture by ingredient/formulation changes.

METHOD

Equipment:

|

CTX Instrument

|

Loadcell 100Kg

|

TA-KSC002 Kramer shear cell with five Blades

|

TA-BT-KIT Fixture Base Table

|

| Texture Pro CT Software |

Settings:

| Test Type: |

Compression |

| Pre-Test Speed: |

1.0 mm/s |

| Test Speed: |

1.0 mm/s |

| Post-Test Speed: |

1.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

60.0 mm |

| Trigger Force: |

50 g |

SAMPLE PREPARATION

Remove the cooled potatoes from storage just prior to testing. Dice the potatoes and weigh out equal amounts for testing. The sample amount should occupy approximately 70 % of the fill capacity of the cell.

PROCEDURE

- Attach the blades to the probe shaft of the instrument.

- Place a fixture base table onto the base of the instrument and loosely tighten the thumb nuts to enable some degree of mobility.

- Insert an empty Kramer shear cell onto the base table with the Perspex side facing the front and tighten into position using the thumb screws.

- Align the blades to the Kramer cell by lowering the blades and re-adjusting the positioning of the Kramer Cell such that the blades can be lowered into the cell without touching the edges of the cell.

- Once alignment is complete, tighten the thumb nuts of the base table to prevent further movement.

- Place a catchment drawer under the Kramer cell to catch any extruded sample.

- Remove the blades by unscrewing the blade holder from the fixture in order that the weighed sample may be placed into the cell.

- Place the weighed sample into the Kramer cell and spread it out to create a level surface.

- Screw on the blade holder onto the fixture. The blades should now be back into their alignment position.

- Lower the blades to a few millimeters above the sample surface.

- Commence the test.

- When proceeding to the next test, remove the blades to enable easy removal of the cell and clean the blades and the cell with water to remove any trace of previous sample.

Note: When optimizing test settings, the hardest sample is best tested first in order to predict the maximum testing range for subsequent samples.

RESULTS

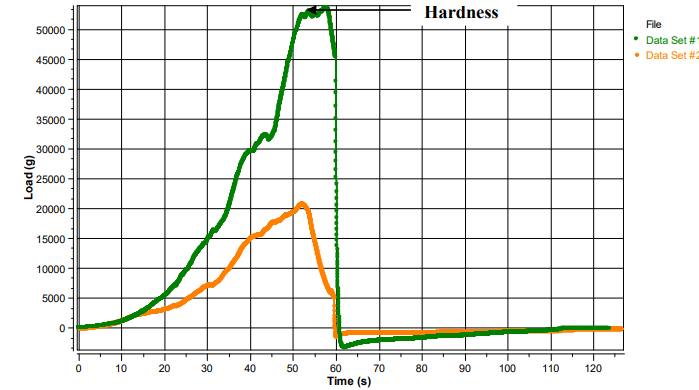

Figure I

Figure I The Load/Time graph for the firmness of potatoes of different cooking times A maximum peak force is a measure of sample hardness, the higher the value the harder the

sample. 2 minutes 8 minutes

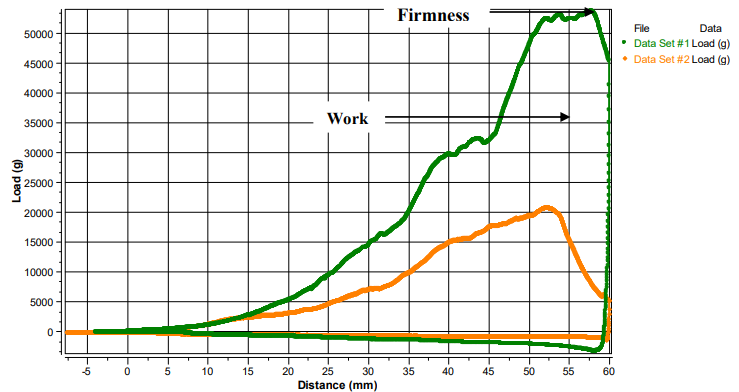

Figure II

Figure II The Load/Distance graph for the firmness of potatoes of two different cooking timesThe maximum peak force is a measure of sample toughness. The area under the curve from the start of the test to the target distant point (60 mm) is a measure of work done.

2 minutes 8 minutes

OBSERVATIONS

When the test begins, the blades travel at a pre-test speed of 1mm/s to the sample surface. When a trigger force of 50 g has been detected at the sample surface, the blades begin to compress the sample over a specified distance (60 mm in this test) at a test speed of 1mm/s during which time the sample is compressed to pack more tightly thus eliminating any air pockets before shearing can begin. The sample is then sheared and extruded through the cell. The maximum force value on the graph is the force required to compress and shear the sample which is a measure of sample hardness. This value correlates with the biting force required to shear (cut) the sample with the teeth on the first bite. The higher the value, the harder the sample, (see Figure 1 and 2). The area under the graph from the start of the test to the target distance (see Figure 2) is a measure of work done. This value correlates with the amount of energy required to overcome the strength of the internal bonds within the sample. The higher the value, the more energy required to deform and shear the sample.

The table below Summarises the results:

| Cook Time |

Hardness (g) |

Work Done (mJ)

|

| 2 minutes |

53600 |

11774.7 |

| 8 minutes |

20845 |

4858.4 |

>>Download PDF of this application note.