Use

To be used in a dishwasher to help clean dishes.

METHOD 1

Test Equipment

Instrument: DV3T Rheometer

Spring Torque: HB

Spindle: HB-3

Speed: 5, 10, 50, 90, 130, 170, 210 and 250 RPM

Temperature: Room Temperature (70°-72°F)

Test Method

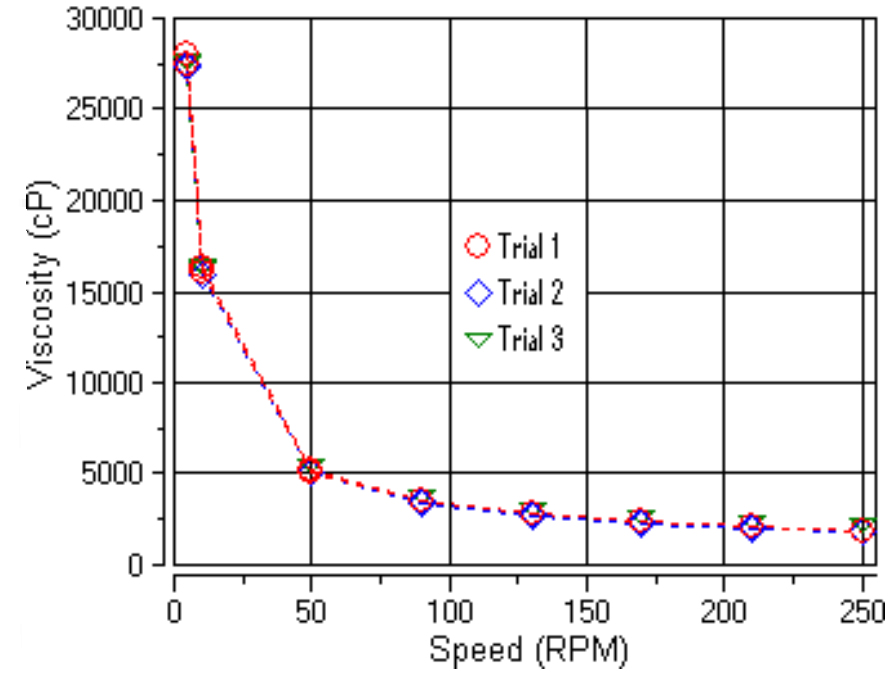

We used a Brookfield DV3THB Rheometer with Rheocalc™ software for automated instrument control and data acquisition. We ran our test at room temperature (70-72°F) in a 600 mL beaker. We used an HB-3 spindle immersed to its immersion mark. Three trials were run to ensure repeatability. Each trial was run in a new portion of the sample. Representative data from the analyses are shown in Figure 1 which shows that the viscosity of the Dishwasher Detergent decreased as the shear rate increased. This behavior is known as “shear-thinning.” Results over the range of shear rates were all on-scale between 10 and 100% of fullscale range torque. Note that all three curves lay on top of one another, which shows excellent repeatability.

Figure 1: Dishwasher Detergent at 70°-72°C

Viscosity vs. Rotational Speed

METHOD 2

Test Equipment

Instrument: DV3T Rheometer

Spring Torque: HA

Spindle: SC4-27 Spindle with 13RPY Sample Chamber

Accessories: Small Sample Adapter, TC-550AP Programmable Refrigerated Bath

Speed: 10, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 120, 130, 140, 150, 160, 170, 180, 190, 200, 210 and 220 RPM

Temperature: 25°C

Test Method

The Small Sample Adapter may be used with various Brookfield Viscometers or Rheometers. In our example, we used a Brookfield DV3THA Rheometer with Rheocalc™ software for automated instrument control and data acquisition. Our test temperature of 25°C was maintained by connecting the Small Sample Adapter water jacket to a Brookfield TC-550AP Programmable Refrigerated Bath.

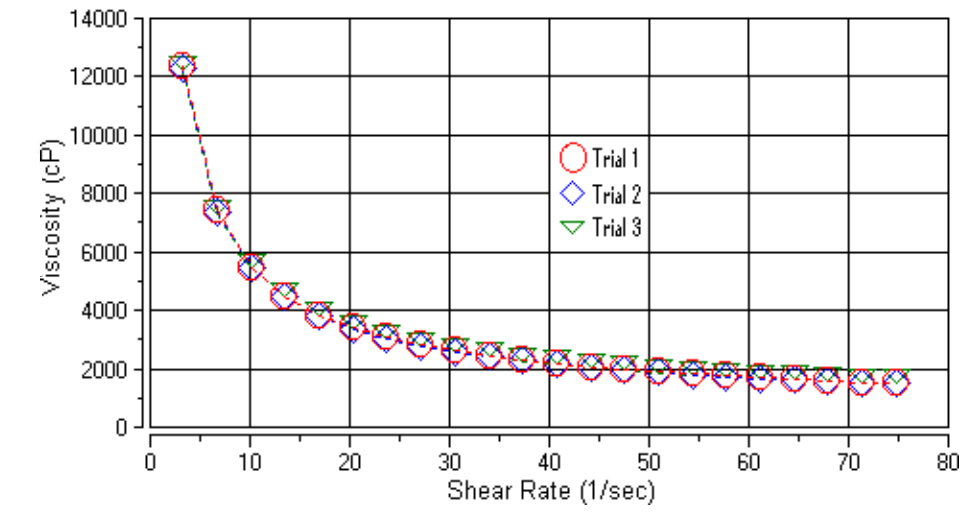

Three different samples were tested to ensure repeatability. A syringe was used to measure 10.4 mL of the sample and dispense it into the chamber. The Small Sample Adapter can be an extremely valuable accessory, especially if you would like to use much smaller samples than required to perform Method 1. Representative data from the analyses are shown in Figure 2.

Figure 2 shows that the viscosity of the dishwasher detergent decreased as the shear rate increased. This behavior is known as “shear-thinning”. Results over the range of shear rates were all on-scale between 10 and 100% torque. Results were repeatable.

Figure 2: Dishwasher Detergent at 25°C

Viscosity vs. Shear Rate

METHOD 3

Test Equipment

Instrument: DV3T Rheometer

Spring Torque: RV

Spindle: V-73 Vane Spindle, Immersed to the Primary Immersion Mark

Speed: 1 RPM

Temperature: Room Temperature (70°-72°F)

Test Method

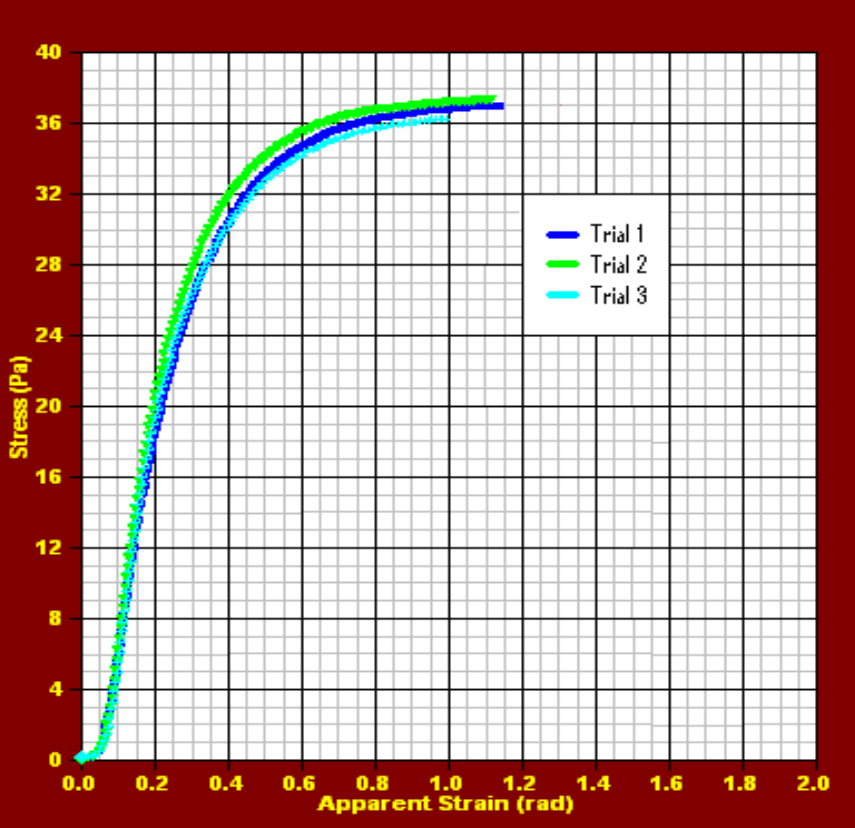

We used the Brookfield DV3TRV Rheometer, with EZ-Yield™ software for automated instrument control and data acquisition. The yield stress tests determine the stress that must be applied to make a material flow. The corresponding apparent yield strain is the deformation at which the sample structure breaks down and starts to flow. The sample was squeezed out of its bottle into a 250-mL beaker, where it was tested. The Vane spindle was immersed to its primary immersion mark. The Vane spindle was immersed into a new portion of the sample for each trial. Figure 3 shows Stress (Pa) vs. Apparent Strain (rad) of the Dishwasher Detergent at 1 RPM. The stiffness or firmness of the material is reflected in the slope or steepness of the stress-strain curve. The yield stress is the maximum stress (around 37 Pa) in each run. The results were repeatable.

Figure 3: Dishwasher Detergent at 70°-72°C

Shear Stress vs. Apparent Strain

<<Download a pdf of this application note.