TEST PRINCIPLE

The test objective is to evaluate the hardness or firmness of wax using a cone probe according to ASTM Standard method D937-92.

BACKGROUND

Waxes are organic products synthetically and naturally produced. They generally tend to be softer at higher temperatures and harder at lower (colder) temperatures. Consequently, the "stickiness" and hardness of some waxes will depend upon the temperature. Hard waxes are less sticky and therefore adhesive. By varying the hardness of the wax using different grades of wax, the adhesive nature or traction of the wax can be altered.

Many cosmetic, medical and personal care products contain waxes. The capability of waxes to produce a good luster, product firmness, along with their moulding properties makes them complimentary to the final texture of the product. Measuring the hardness (firmness) of a wax determines whether a wax of interest will be suitable for a particular product in producing the desired properties.

The standard method D937-92 uses a penetrometer to determine the penetration depth of a standard cone under defined conditions. The CT3 texture analyzer has adopted this standard method using the specified parameters as well as providing alternative methods of measurement such as determining the force to penetrate a specified distance. Cone angles can range from 15–90°.

METHOD

| Equipment: |

CT3 with 4.5 kg Load Cell |

| |

30° Conical Probe |

| |

TexturePro CT Software |

Settings:

| Test Type: |

Tension |

| Pre-Test Type: |

1.0 mm/s |

| Test Speed: |

2.0 mm/s |

| Post-Test Speed: |

2.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

30 mm |

| Trigger Force: |

20 g |

Note:

It is recommended that the pre-test speed be the same as or less than the test speed for accurate trigger detection; for example, 2 mm/s test speed will require ≤ 2 mm/s pre-test speed.

Very soft samples will not be able to achieve a 150 g force. In such circumstances, the softest sample should be tested first to determine if the procedure works. A suitable method may need to be developed.

SAMPLE PREPARATION

In the standard method, the sample is melted to 82°C and poured into a standard container. The sample is cooled to room temperature for 16 to 18 hours (refer to the ASTM standard method for further information). An alternative method (also used in this test) is to test samples directly from their original containers. If using this method, the dimensions of the chosen container must be reported and applied to subsequent tests. The surface of the sample must remain intact and un-tampered as this may affect the result.

PROCEDURE

1.

Attach the cone probe to the load cell.

2.

Align the sample centrally under the cone probe and 15 mm from the edge of the container.

3.

Start the penetration test.

4.

When the probe pulls out of the sample, firmly hold the container to prevent it from lifting.

5.

When proceeding to the next test, wipe the cone probe with a clean dry cloth to remove all traces of wax.

Note:

The temperature of the cone must also be at room temperature before commencing the test.

This test measures the distance required to generate a load of 150 g. An alternative method can also be used where the force required to penetrate a specified distance is measured.

RESULTS

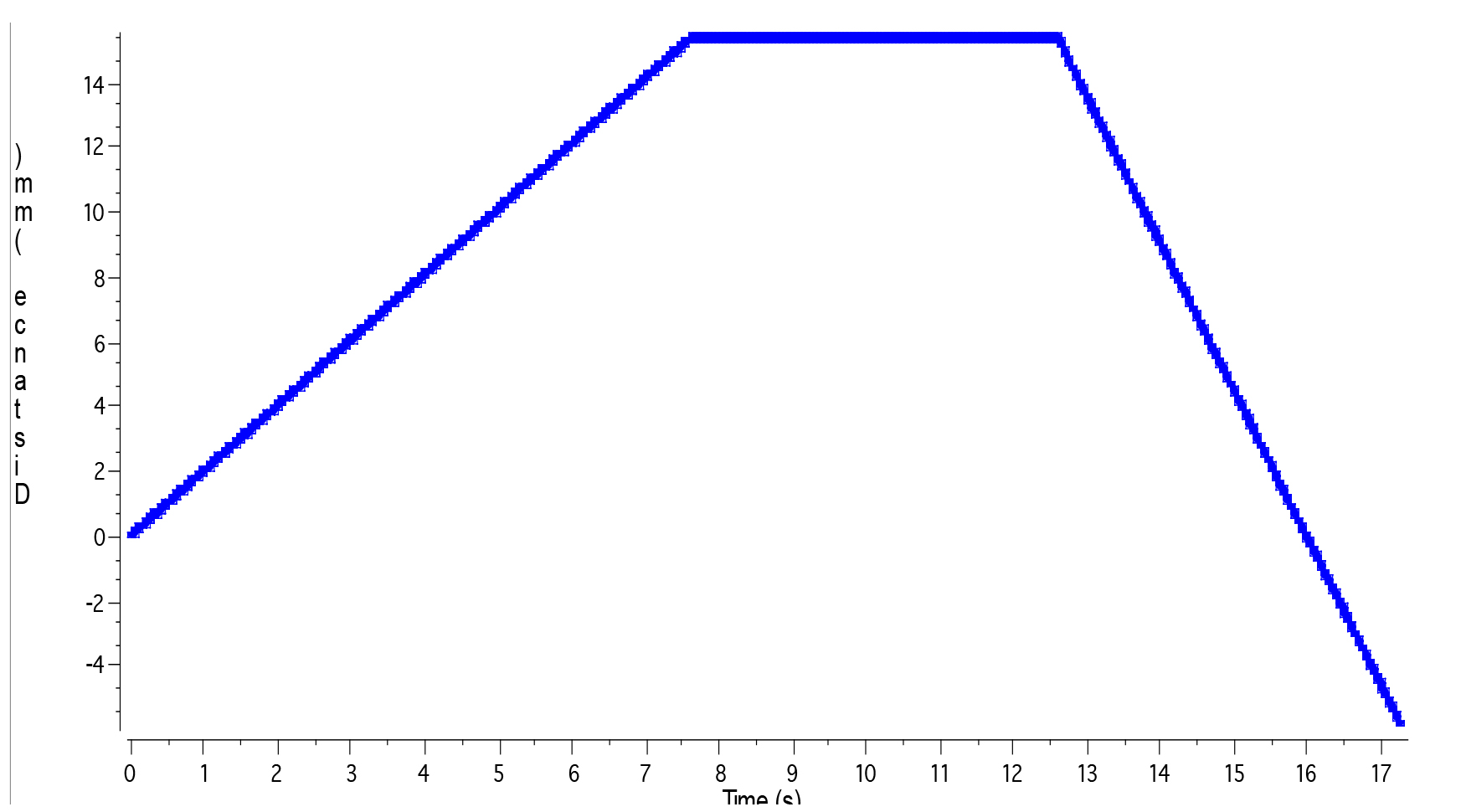

The following is a typical TexturePro CT plot. The graph shows the wax hardness of a Petroleum Jelly using a conical probe.

Figure I

The graph in Figure I shows the hardness of the Petroleum Jelly measured from a 50 mL, 3.5 x 5.0 cm.

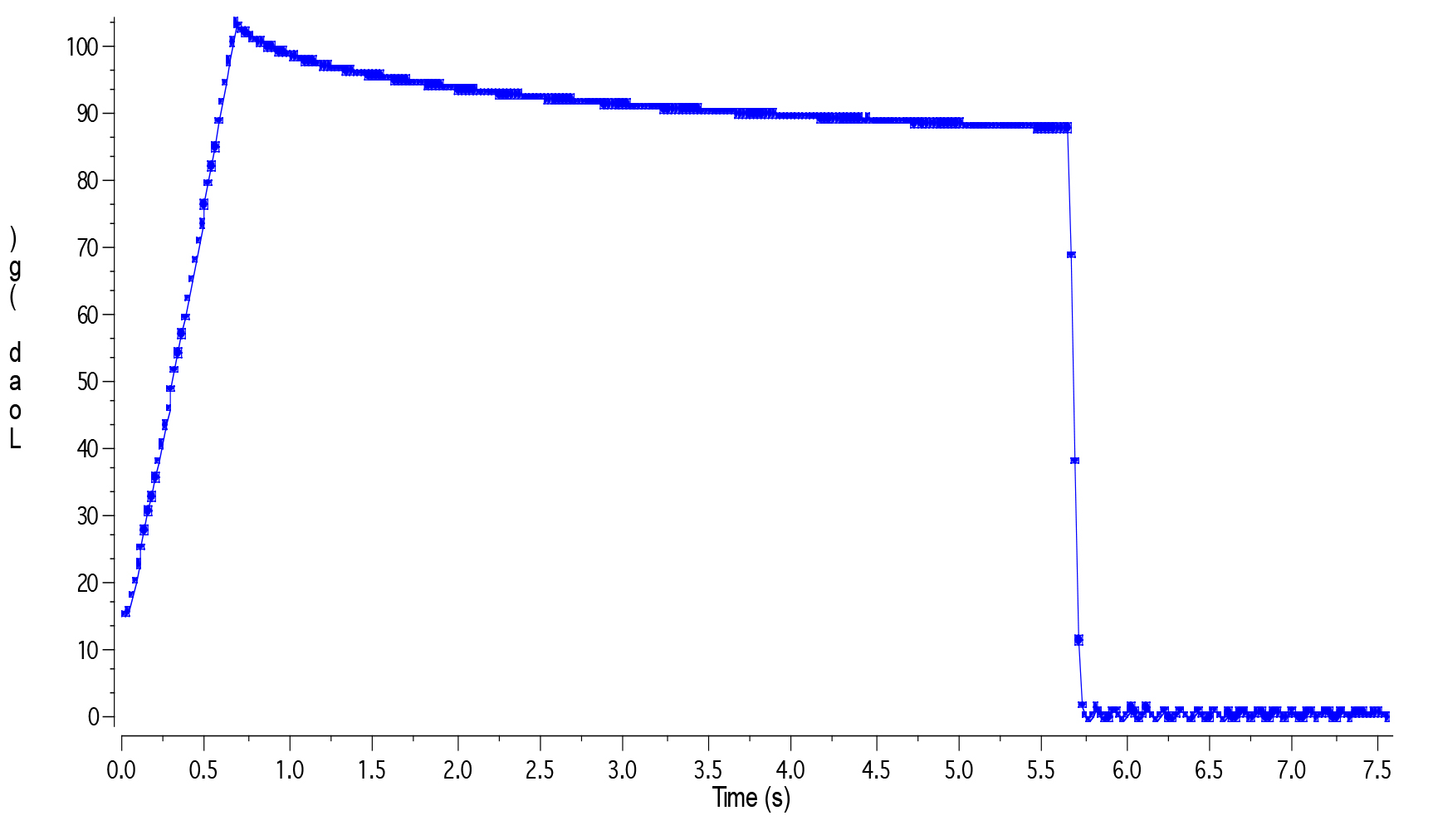

Figure II

The graph in Figure II shows the load versus time for the hardness of Petroleum Jelly.

OBSERVATIONS

When a trigger force of 5 g has been attained, the probe proceeds to penetrate the sample until a force of 150 g has been achieved. This is followed by a hold time of 5 seconds before the probe withdraws from the sample at a post-test speed of 10 mm/s. The distance of penetration depends upon the hardness of the sample. A large penetration distance will indicate a soft sample whereas a small penetration distance will indicate a harder sample. The test is useful for comparing the hardness of different waxes in determining the choice of wax for a particular product.

The table below shows the mean values for a Petroleum Jelly tested at multiple sites.

Deformation at Hardness

(mm) |

Work Done Hardness

(mJ) |

| 17.05 ± 2.4 |

9.74 ± 1.22 |

>>Download a pdf of this application note.