TEST PRINCIPLE

Comparison of product softness of full, medium and low-fat soft cheese using 45° cone probe to determine the spreadability and softness of cheeses.

BACKGROUND

Soft cheeses are cheeses with moisture content between 48% and 80%. Full fat soft cheeses should not contain more than 60% moisture with a fat content greater than 20%. Texture analysis plays a vital role in the quantification of curd characteristics where it acts as a rheological predictor of finished product quality, as well as a potential indicator of moisture content. Stabilizer systems build solids, increase viscosity and enhance product mouth-feel (creamy texture) and flavor release. Texture analysis thus plays an essential role in the development of low fat foods where the product developer wishes to mimic the texture profile of full fat counterparts.

This test compared:

1.

Full fat = 30% fat, with 8% protein

2.

Light = 15% fat, with 12% protein

3.

Extra light = 6% fat, with 15% protein

METHOD

| Equipment: |

Texture Analyzer with 1500g load cell |

|

Fixture Base Table (TA-BT-KIT) |

|

Conical Probe 45° (TA15) |

|

Texture Pro Software |

Settings:

| Test Type: |

Compression |

| Test Speed: |

1mm/s |

| Target Value: |

20mm |

| Trigger Force: |

4.5g |

PROCEDURE

- Samples were removed from refrigerator at 6.8°C.

- The sample was located beneath the test probe and evaluated within original container.

- Three replicate tests were made within the same sample. Three minutes elapsed between the first and last test.

TYPICAL RESULTS

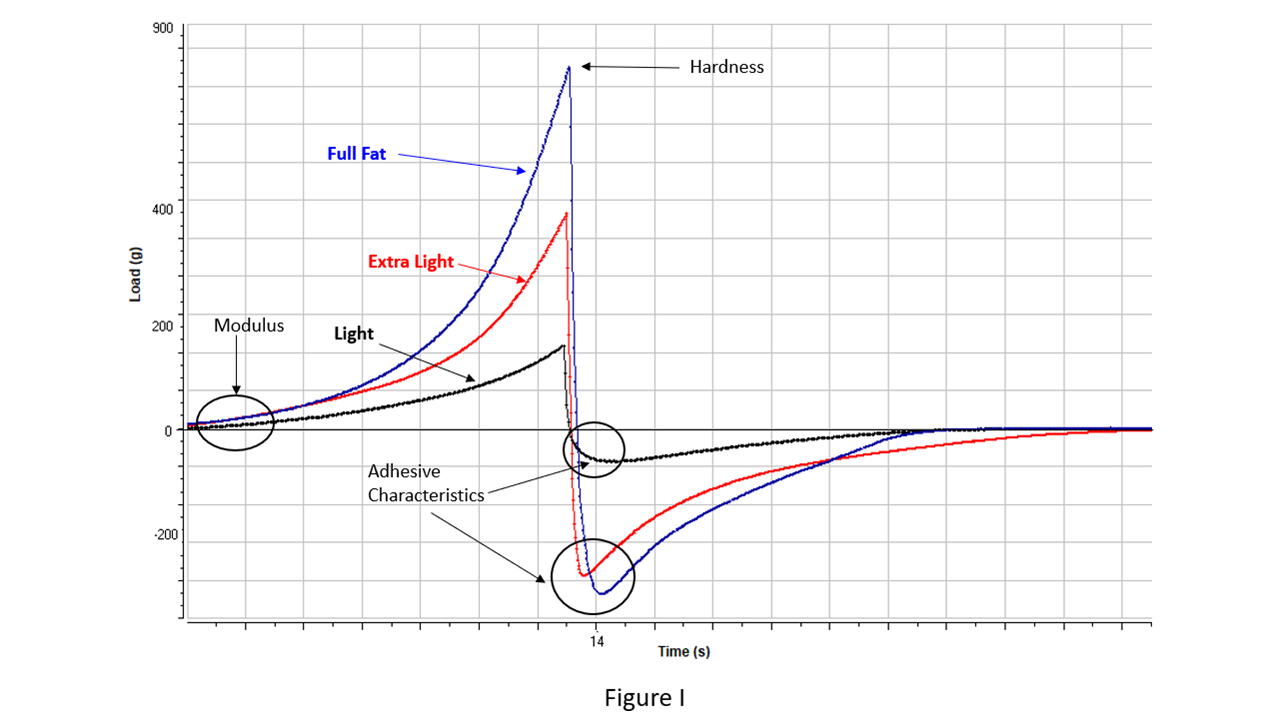

The force deformation curves of the three products show dramatic variation of textural characteristics. The full fat product is the most firmly set, possessing the greatest values for modulus, hardness and adhesion. The half fat product had the lowest values of the three soft cheeses. The extra light sample exhibited characteristics between those the other two materials.

PARAMETERS

| HARDNESS (g) |

Peak positive load attained in full cycle; Force required to attain a given deformation. |

| ADHESIVE FORCE (g) |

Peak negative load attained in full cycle; Force required to pull probe from sample. |

| MODULUS (g/cm2) |

Ratio of sample stress divided by strain during the first compression cycle e.g. the slope of force; deformation curve within linear region. It is representative of sample rigidity. |

RESULTS

| |

FULL FAT |

LIGHT |

EXTRA LIGHT |

| HARDNESS (g) |

897 |

180 |

356 |

| ADHESIVE FORCE (g) |

-140 |

-33 |

-60 |

| MODULUS (g/cm2) |

34.6 |

5.7 |

11.1 |

CONCLUSION

The full fat product has the firmest texture. The light product is very soft in comparison. The extra light product falls between both the full fat and light samples, with a structured consistency resulting from stabilization with increased milk protein and additives. The inclusion of these compounds failed to mimic the overall profile of the full fat sample.

>>Download a pdf of this application note.