TEST PRINCIPLE

Evaluation of the hardness/firmness of cooked chicken meat using a five bladed Kramer Shear Cell (TA-KSC002)

BACKGROUND

Texture is normally associated with the hardness and structure of meat. There are several factors that will influence the hardness and structure of meat including the water holding capacity (WHC), rigor status of the meat, marbling fat, connective tissue content, and muscle bundle size. Having a high WHC produces a meat with stronger structure and a dry texture. On the other hand, meat with a low WHC will have a soft, moist texture and the toughness of the meat is lost.

The Kramer shear cell with its multiple blades allows for samples of variable geometry to be sheared. The results for hardness and work done are therefore an average of the forces required to shear the sample of variable geometry. This fixture incorporates the textural methods of compression, shearing and extrusion through slots in the base of the cell.

METHOD

| Equipment: |

|

| Instrument: |

CTX with 50 Kg |

| Accessory: |

TA-KSC Kramer Shear cell |

|

TA-BT-KIT Fixture Base Table |

| Software: |

Texture Pro Software |

Settings:

| Test Type: |

Compression |

| Pre-Test Speed: |

2.0 mm/s |

| Test Speed: |

2.0 mm/s |

| Post-Test Speed: |

2.0 mm/s |

| Target Type: |

Deformation |

| Target Value: |

35 mm |

| Trigger Force: |

5 g |

SAMPLE PREPARATION

- Remove the sample from the place of storage just prior to testing.

- Weigh equal amounts of sample for testing

PROCEDURE

- Attach the probe containing the blades to the probe shaft of the instrument

- Place the fixture base table onto the base of the instrument and loosely tighten the thumb nuts to enable some degree of mobility

- Fix the Kramer shear cell to the fixture base table with the Perspex side facing the front and tighten into position using the thumb screws

- Slowly lower the arm of the instrument and align the blades with the shear cell by re-positioning the fixture base table so that the blades can clearly penetrate the shear cell through the slots without any friction effects caused by the blade touching the sides of the cell.

- Once alignment is complete, tighten the thumb nuts of the fixture base table to prevent further movement.

- Remove the blades by unscrewing the thumb screw on the fixture to provide room for placing the sample into the shear cell.

- Place a weighed amount of sample into the shear cell and then screw back the blades onto the fixture

- Lower the instrument arm so that the blades are a few millimeters from the sample surface.

- Commence the test

Note: When proceeding to test a fresh sample, wash the fixture to remove traces of previous sample.The weighed amount of sample for testing must be consistent through out the tests

RESULTS

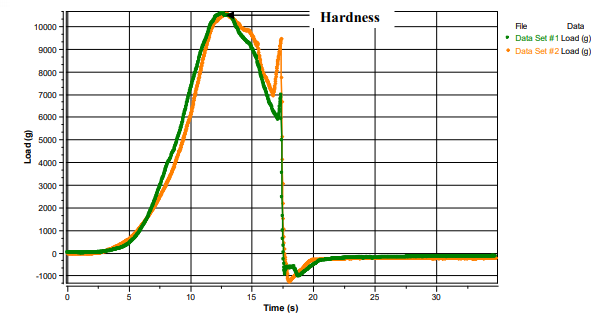

Figure I

Figure I The Load/Time graph for the hardness/firmness of 30g cooked chicken using the five bladed Kramer Shear Cell

Two sample results from the same batch have been overlaid. The maximum peak force is a measure of sample hardness/firmness. Two samples have been tested and overlaid.

Figure II

Figure II The Load/Distance graph for the hardness/firmness of 30 g of cooked chicken.

Two sample results of the same batch have been overlaid.The maximum peak force is a measure of sample hardness. The area under the graph from the start of the test to the target distance point (30 mm) is a measure of work done.

OBSERVATIONS

At the start of the test, the blades approach the meat surfaces at a pre-test speed of 2 mm/s. When a trigger force of 10 g has been detected at the sample surface the blades proceed to compress and penetrate through the sample over target distance of 35 mm at a test speed of 2 mm/s.

The maximum force value on the graph is a measure of sample hardness/firmness. This value correlates with the amount of force required by the teeth to compress the sample; the higher the value, the firmer the sample (see Figure 1 and 2).

The area under the graph from the start of the test to the target distance of deformation (see Figure 2) is a measure of work done. This value correlates with the amount of energy required to overcome the strength of the internal bonds within the sample. The higher the value, the more energy required to breakdown the sample.

The table below Summarises the results taken from 12 tested samples of cooked chicken from the same batch:

| Sample |

Hardness (g) |

Work Done (mJ)

|

| Cooked Chicken |

14548 ± 600 |

1344.3 ± 29.4 |

>>Download PDF of this application note.