TEST PRINCIPLE

The objective was to compare the consistencies of two types of hair gels by back extrusion.

BACKGROUND

Formulating hair gels largely depends upon the required end product consistency, therefore influencing the choice of material to use. One desirable factor in product development is having a product that easily squeezes out of a tube and breaks off cleanly after squeezing. With the use of forward and backward extrusion tests, these consistencies can be assessed. The forward extrusion simulates the force required by the consumer to extrude the sample and the backward extrusion is an indication of the products physical failure and viscosity.

METHOD

| Equipment: |

CT3 with 4.5 kg Load Cell |

| |

Round Base Table (TA-RT-KIT) |

| |

Back Extrusion Cell (TA-BEC) |

SETTINGS

| Test Type: |

Compression |

| Pre-Test Type: |

1.0 mm/s |

| Test Speed: |

2.0 mm/s |

| Post-Test Speed: |

2.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

25 mm |

| Trigger Force: |

10 g |

Note: It is recommended that the pre-test speed be the same as or less than the test speed for accurate trigger detection; for example, 1 mm/s test speed will require ≤ 1 mm/s pre-test speed.

The target distance chosen should be such that the probe does not deform the sample to more than 75% of sample depth, otherwise the base effect may affect the results.

PROCEDURE

1. Position the extrusion disc centrally over the sample container.

2. Remove the sample kept at a specific temperature (E.g., 25°C) from storage.

3. Fill the extrusion container with the sample to about 75% full.

4. Calibrate the probe to a specified starting distance (E.g., 30 mm) above the top of the container or sample surface. This will ensure the probe returns to the same position above the samples after each test enabling comparisons of cohesiveness and ‘work of cohesion’ of samples.

5. When the probe pulls out of the sample, firmly hold the container to prevent it from lifting.

RESULTS

A comparison of consistencies of two types of hair gel by back extrusion.

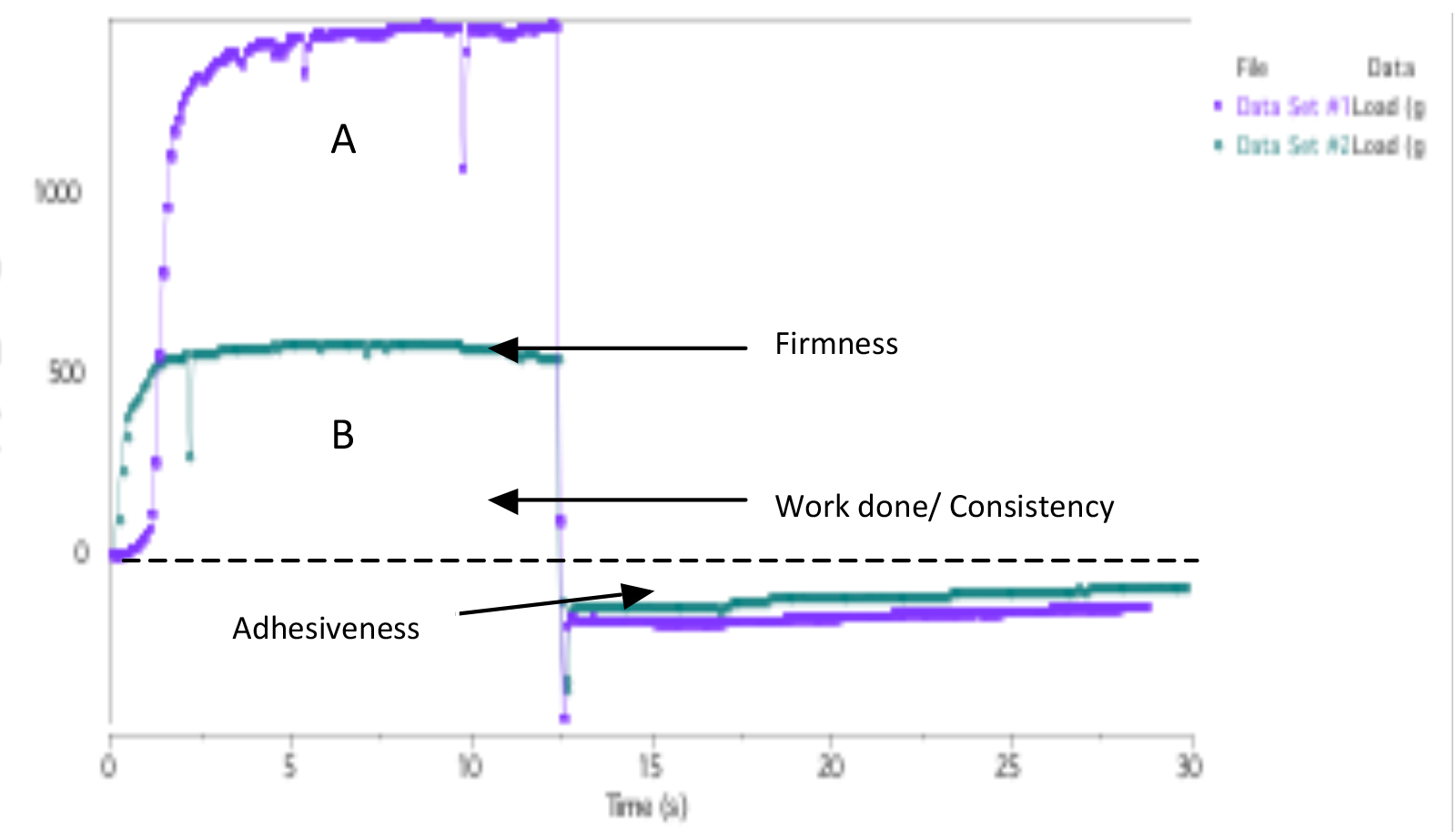

Figure I

The graph in Figure I shows the consistencies of two types of hair gels stored and tested at 21°C in a 40 mm diameter back extrusion container.

Data Set #1: Sample A (Premium Hair Gel)

Data Set #2: Sample B (Budget Hair Gel)

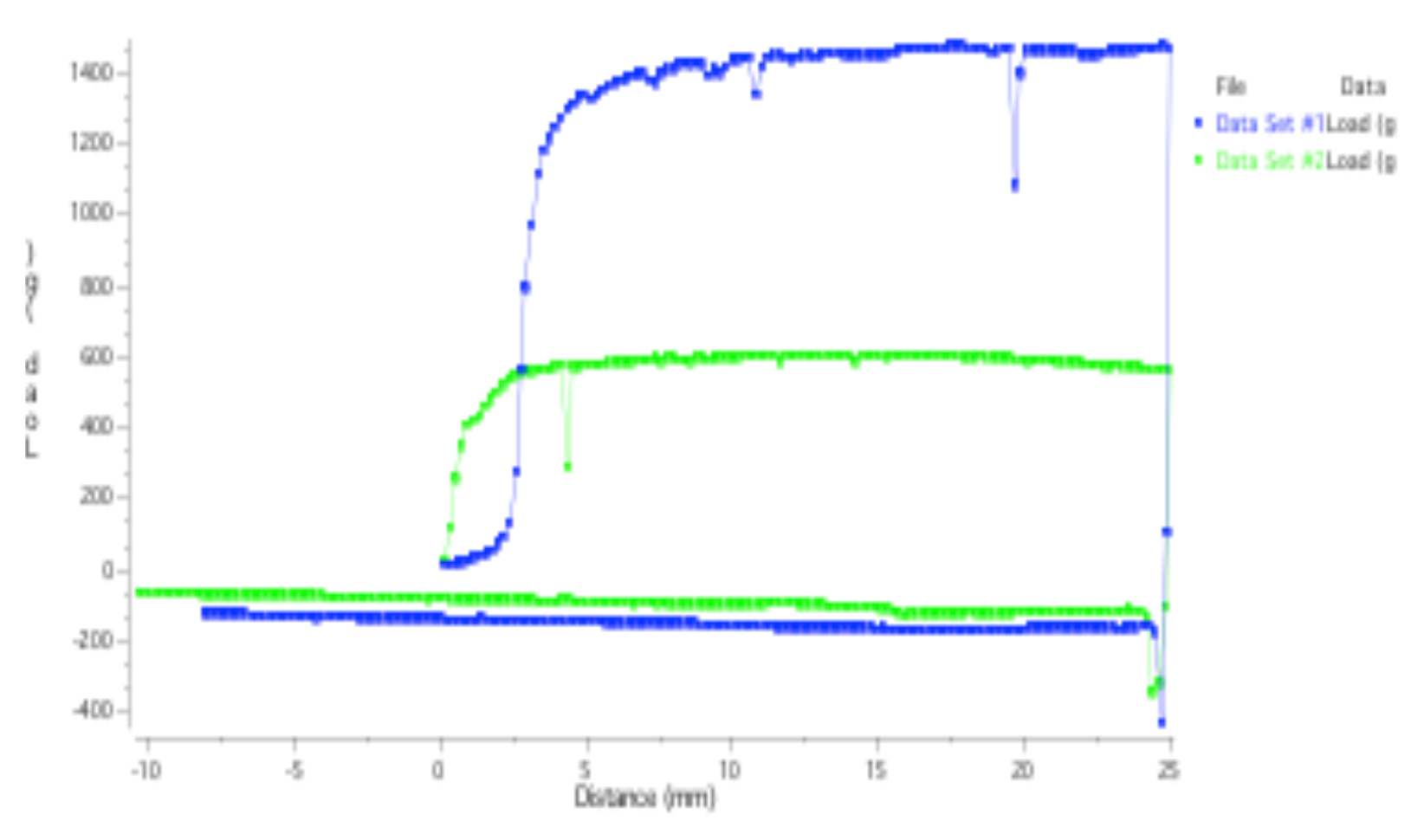

Figure II

Figure II is of a load deformation graph showing the consistencies of two types of hair gel.

Data Set #1: Sample A (Premium Hair Gel)

Data Set #2: Sample B (Budget Hair Gel)

OBSERVATIONS

When a trigger force of 10 g has been achieved, the disc plunger begins to deform the sample to a specified distance (25mm) after which the probe returns to its starting position. The maximum force represented as a peak on the graph measures firmness; the higher the value, the firmer the sample. The area under the positive part of the graph indicates sample consistency (work done to hardness 1); the higher the value, the thicker and the higher the consistency of the sample. As the probe returns to its starting position, the initial lifting of the weight of the sample on the upper surface of the disc produces the negative part of the graph resulting from back extrusion. This gives an indication of the cohesiveness and resistance of the sample to separate (flow off) from the disc. The maximum negative force on the graph indicates sample adhesive force; the more negative the value, the more “sticky” the sample. The area under the negative part of the graph is known as the adhesiveness (energy required to break probe sample contact) and can give an indication of the cohesive forces of the molecules within the sample. The higher the value, the more energy required to break the probe sample contact as the probe withdraws from sample. From Figure 1, sample A is more firm and has a higher consistency than sample B. Also sample A has a higher adhesive component than sample B.

>>Download a pdf of this application note.